In today’s rapidly evolving industrial landscape, automation is revolutionizing fabrication, setting new standards in efficiency, accuracy, and productivity. From offshore platforms and oil-gas facilities to renewable energy projects and architectural developments, automation is driving precision and speed in fabrication across sectors.

At Al Bany Group, we embrace this transformation by offering industry-specific fabrication automation solutions powered by advanced manufacturing technologies. Whether it’s the construction of hydrogen-ammonia plants, metals-mining infrastructure, or electrical-instrumentation systems, smart automation is delivering tangible value.

1. The Evolution of Fabrication Automation

Fabrication has transitioned from manual craftsmanship to mechanical assistance, and now into the era of industrial automation. What once required large teams and long hours can now be completed by integrated systems with minimal human intervention.

Today’s automated fabrication systems are widely used in sectors like offshore, oil-gas, petrochemicals, and ports-marine, where safety, efficiency, and scalability are critical. Smart automation helps streamline workflows, reduce errors, and accelerate time-to-market, even for the most complex fabrication tasks.

2. CNC Machining Automation: Core of Precision Engineering

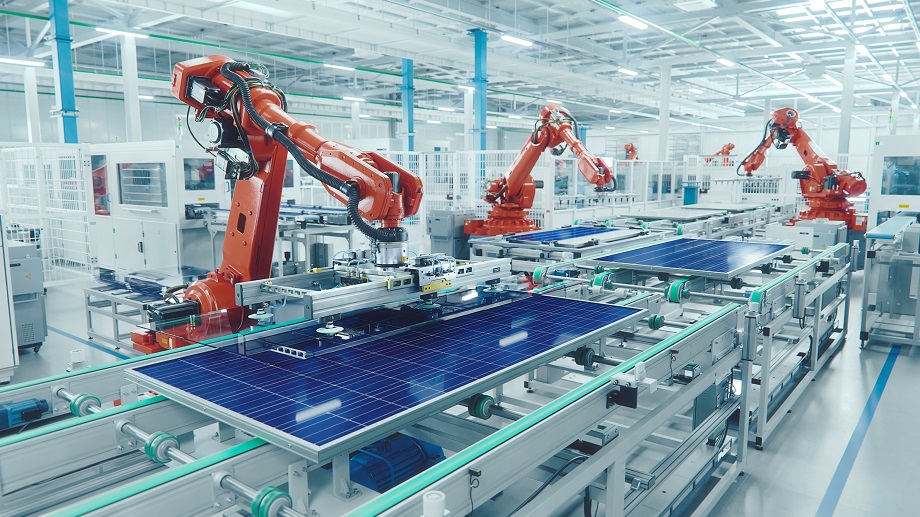

A major pillar of modern fabrication is CNC machining automation, which plays a vital role in industries like metals-mining, architecture, and renewables. CNC (Computer Numerical Control) machines, when automated, can handle 24/7 operations with consistent output and zero fatigue.

These machines excel at producing custom parts for hydrogen pipelines, marine structures, or solar panel frames. At Al Bany Group, our CNC-enabled workshops ensure that every component meets exact design specifications — critical for structural integrity in large-scale industrial projects.

3. Smart Factory Solutions for Industry-Specific Demands

Smart factory solutions bring intelligence to fabrication. Using IoT devices, AI analytics, and real-time dashboards, factories can monitor performance, identify issues, and adjust processes automatically.

This technology is especially beneficial in high-risk environments like petrochemicals, desalination plants, and electrical-instrumentation systems. Smart factories can detect faults before they lead to failures, ensuring safety and uptime — both of which are essential in industries like poccrts-marine and offshore fabrication.

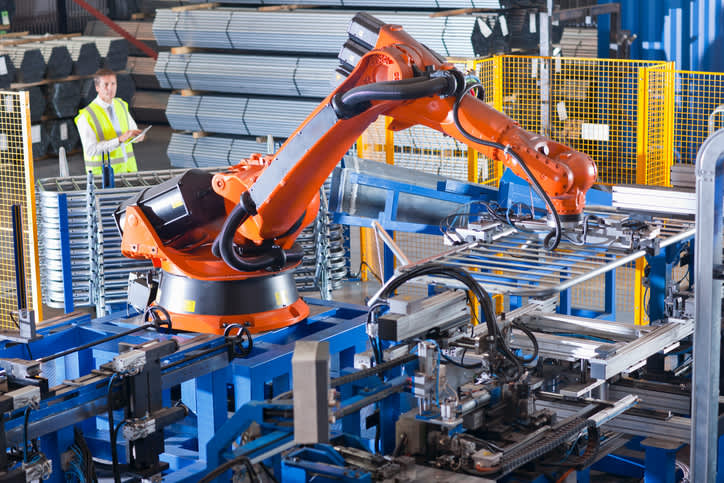

4. Robotics in Fabrication: Replacing Risk with Reliability

Robotics in fabrication is no longer futuristic — it’s a standard in sectors where precision and speed are critical. Robotic arms handle welding, cutting, material handling, and assembly with unmatched consistency.

In environments like offshore rigs, hydrogen-ammonia plants, and oil-gas refineries, robots help reduce human exposure to hazardous conditions. With robotic automation, Al Bany Group delivers safe, scalable solutions without compromising on quality or compliance.

5. Key Benefits of Automated Fabrication Systems

Adopting automated fabrication systems results in numerous benefits across sectors:

- Increased Productivity: Especially in large-scale industries like renewables and metals-mining.

- Reduced Human Error: Vital in precision-driven environments like architecture and instrumentation.

- Enhanced Safety: Robots and sensors reduce risks in oil-gas and petrochemical projects.

- Lower Costs: Long-term savings through reduced labor, waste, and downtime.

With a robust presence across sectors, Al Bany Group brings these benefits to clients globally — from port construction to green hydrogen infrastructure.

6. Advanced Manufacturing Technologies Across Industries

Advanced manufacturing technologies such as 3D printing, digital twins, machine vision, and AI-powered inspection are accelerating innovation across industries. These technologies support everything from desalination plants to hydrogen-ammonia storage units, ensuring better planning, faster execution, and improved lifecycle management.

Al Bany Group utilizes these tools in our fabrication units to enhance operational excellence, whether it’s for building offshore modules or architectural steel frameworks.

7. Real-World Applications Across Sectors

Here’s how fabrication automation is delivering value across industries:

- Offshore: Modular fabrication of oil platforms using robotic welding and automated QC.

- Renewables: CNC-fabricated components for wind turbines and solar farms.

- Oil-Gas: Automated piping fabrication and assembly for complex refineries.

- Petrochemicals: Smart factory-enabled monitoring for pressure vessels and reactors.

- Hydrogen-Ammonia: Precision fabrication of tanks, pipelines, and control skids.

- Metals-Mining: Structural component fabrication using robotics and CNC.

- Architecture: Intricate design fabrication using laser cutting and robotic assembly.

- Electrical-Instrumentation-Desalination: Automation in control panel wiring and skids.

- Ports-Marine: Steel structure fabrication for jetties, platforms, and marine cranes.

8. Overcoming Challenges in Automation Adoption

While the potential is vast, adopting automation also brings challenges:

- Capital Investment: Especially for industries with variable demand like architecture and desalination.

- Training Requirements: Advanced systems demand skilled operators, especially in instrumentation.

- System Integration: Retrofitting old fabrication setups in oil-gas or marine sectors can be complex.

At Al Bany Group, we offer end-to-end automation integration — from training and installation to maintenance — making the transition seamless and cost-effective.

9. Automation Driving Sustainability and Compliance

Automation also supports sustainability, helping companies meet carbon-reduction goals. Whether it’s energy-efficient robotic welding in hydrogen-ammonia projects or waste-reduction strategies in petrochemical fabrication, automation aligns with green manufacturing principles.

Governments and regulators are increasingly requiring digital traceability and efficiency — areas where smart fabrication systems deliver measurable results.

Conclusion: Shaping the Future with Smart Fabrication

As the industrial world moves towards a digitally connected, sustainable future, advancing fabrication through automation becomes not just a trend but a necessity. Whether you’re in offshore engineering, electrical-instrumentation, or renewable energy, the integration of CNC machining automation, robotics, and smart factory solutions unlocks efficiency, safety, and innovation.

At Al Bany Group, we stand at the forefront of this transformation, delivering tailored, future-ready solutions across industries — from ports and mining to architecture and hydrogen infrastructure.